Galvanizing plant

Strona główna » Galvanizing plant

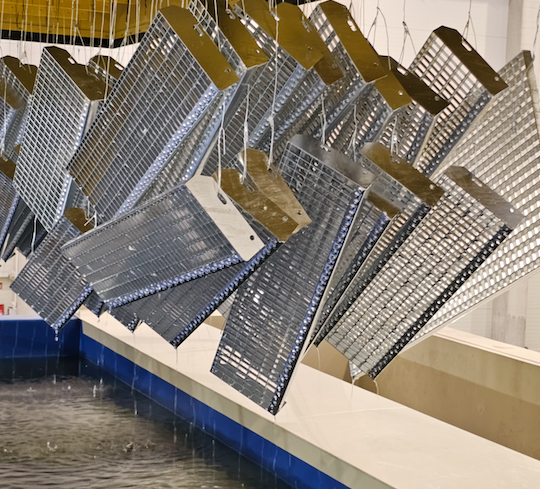

Dumat anti-corrosion galvanizing plant

Find out how to effectively protect the material in our galvanizing plant, using the most effective anti-corrosion hot-dip galvanizing method on the market.

Characteristics of galvanizing plant

Our galvanizing plant in Mysłowice is one of the most modern buildings of this type in Europe. It was established in 2023, and despite its short existence, hundreds of companies from Poland and other countries have already used its services, including: Czech or German.

Experienced employees and modern technologies

The jewel in the crown of our galvanizing plant is a modern galvanizing kettle with dimensions of 7 x 1.6 x 3.3 meters, which allows work on steel with a maximum weight of up to 5 tons. The proper course of the process is supervised by qualified staff with many years of experience in the galvanizing industry.

The galvanizing method used

Our galvanizing plant uses the most effective method called hot-dip galvanizing. Steel elements are immersed in liquid zinc at a temperature of approx. 450'C. The coating obtained in this way protects the steel and guarantees protection against corrosion.

How to prepare steel for galvanizing?

The key to obtaining a good quality surface after anti-corrosion hot-dip galvanizing is to receive properly prepared steel from the client. The material should be free of contaminants such as paints, oils, greases, silicone agents or remnants of old coatings. The client is responsible for their removal.

Not every steel will allow you to obtain the effect of a shiny, protective layer of appropriate thickness. Free-cutting steels containing sulfur, as well as materials with a silicon content exceeding 0.03%, are not suitable for galvanizing. Therefore, it is recommended to use the S235 and S355 variants.

It is also important that the structure undergoing the process allows the free flow of zinc and its subsequent deaeration. Our company can be commissioned to make appropriate technological holes for an additional fee.

More necessary information can be found in the schedule of conditions for accepting material for hot-dip galvanizing at the Dumat Sp. galvanizing plant. z o. o.